The Best Guide To Installing Laminate Flooring

Wiki Article

Excitement About Flooring Stores

Table of ContentsGetting The Hardwood Floor Installation To Work6 Easy Facts About Hardwood Flooring Cost DescribedThe Hardwood Flooring DiariesHardwood Floor Installation for DummiesAll about Hardwood Flooring CostAll About FlooringThe 4-Minute Rule for Flooring Installation

Leave the first coat for 1 day as you wait on it to dry. You should still leave the garage well-ventilated and also prevent going in the space as it dries (hardwood flooring). Before using the second layer, examine the flooring for any type of problems. If there openings or splits, utilize the epoxy filler and await 12 16 hours for it to completely dry.Our epoxy flooring installers will certainly also justify the material with specialist installation services.

Close this dialog home window Share & More Back to tale Talk about this job this web link is to an external website that may or might not fulfill access guidelines.

Examine This Report on Vinyl Flooring

The procedure of measuring, pigmenting, blending, dual potting, pouring and spreading out is duplicated until the floor is completed. Glass, Cast 3 epoxy coating material has outstanding self-levelling residential properties, so will only call for easy work to guarantee that it has full protection and a constant thickness - after that the resin will certainly do the rest of the job.Glasscast 3 is additionally self-degassing so the bubbles will stand out by themselves, although we noticed a tiny patch of floor where bubbles really did not appear to be popping - this can be because of a small patch of flooring not being pre-sealed - to overcome this we swiftly overlooked the surface area with a propane torch to break them.

Once you more than happy with the flooring it's time to secure the room as well as leave it to totally cure - this will enable the resin to degas, self-level as well as treatment to a remarkable high gloss coating similar to this! Remember it is really essential to seal the space to make certain that there are no drafts as this could trigger dust as well as particles to land in the material throughout the remedy.

The Basic Principles Of Flooring Installation

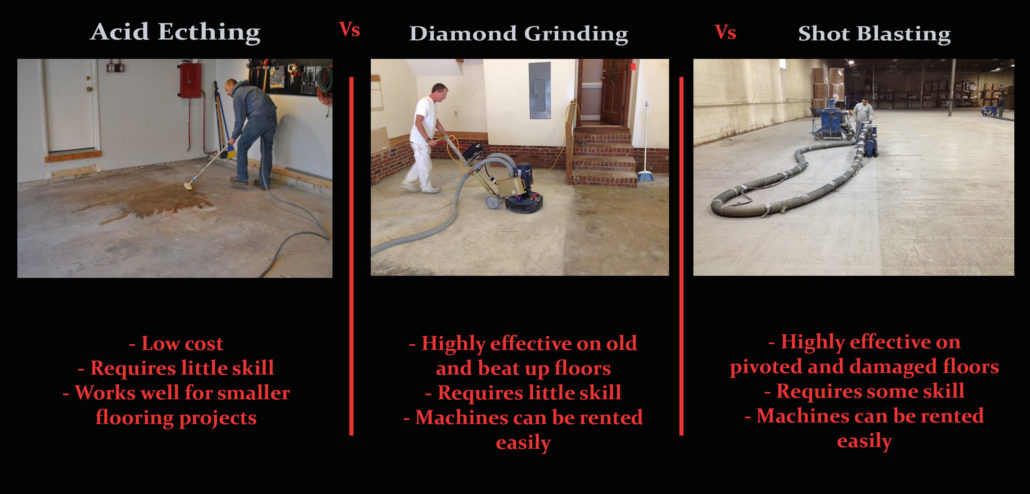

The below guide is a summary of the actions on just how to use epoxy floor paint. Such epoxy systems are typically used with one layer of primer & 2 coats of epoxy floor layer.A Self leveling epoxy floor tends to have a. The listed below video clip describes the distinctions in between a roller used and a self leveling floor. Step 1. Preparing the surface before using the epoxy Prep work of the substrate is essential in order to ensure adhesion between the epoxy product as well as the substratum.

The Best Guide To Laminate Flooring

Making use of a flooring grinder enables you to use different kinds of grinding tools relying on your requirements. As an example if you need to grind rough concrete, you need to utilize a hostile and also rugged ruby device. If you need to give the existing surface a light sanding, you can select instead to utilize a high grit fining sand device.This is why we apply epoxy guide. Constantly prime the flooring, do not think cases that priming is not essential. Priming will give your floor a longer life and better adhesion to the substratum. Furthermore it will certainly secure the substratum as well as minimize the danger of bubbles as well as gasses in your final epoxy coat.

Make certain that the areas are ventilated correctly. In some cases, you will apply the guide and notice that the item gets very quickly soaked up by the substratum. This is very common with messy as well as soft cement based have a peek at these guys floorings. on top of the first one. Make use of a correct electric mixer to mix the An as well as B element of the guide.

The Buzz on Hardwood Flooring Cost

Most likely it will additionally need a bit of sanding before proceeding to the following step. A number of days have probably passed given that you began the procedure of installing your epoxy Related Site floor. If you have actually done all the previous actions properly, you are ultimately all set to use the initial coat.

You will require to gently sand these areas to get rid of any marks that could be visible on the final floor. Use a vacuum cleaner to collect any dirt.

Some Known Factual Statements About Installing Laminate Flooring

Ensure that all the brand-new cracks and also openings are secured & filled up prior to beginning the following coat. If essential wait an added completely dry for the cement to completely dry prior to site here re-coating. If you complied with the epoxy flooring procedure in this article, after that the last layer ought to be the simplest step.

This program was developed for applicators that desire to get into epoxy flooring. You will obtain that has actually been distilled into over 20 lessons - flooring installation.

The 30-Second Trick For Flooring

Action 2: Inspect Weather Condition Forecast Before you begin make sure the air temperature is 60 degrees and rising which your slab goes to a minimum of 50 levels. It will certainly be near difficult for the epoxy to establish if you attempt to do this in the winter months. Step 3: Sweep It Completely Make use of a mop to cleanse the piece.The objective is to not over-wet the floor so it will also completely dry rapidly. Step 6: Apply Etch Pretreatment Mix the citric acid concrete etch with cozy water per the guidelines. Then apply, scrub, and squeegee off the floor likewise as the degreaser. The citric acid will aid open up the leading pores of the concrete so the epoxy sticks well.

Allow longer completely dry times in cooler temperature levels. Step 8: Examination For Existing Sealant Check to see if there is still leading sealer on the floor. Drip water onto the slab. If the water grains up, there is an existing sealer that might hinder the adhesion of the epoxy. Depending on just how much sealer is left, you may need to repeat the etching procedure.

Report this wiki page